TSMC Raises Sales Outlook, Affirming Global Chip Kingpin Role

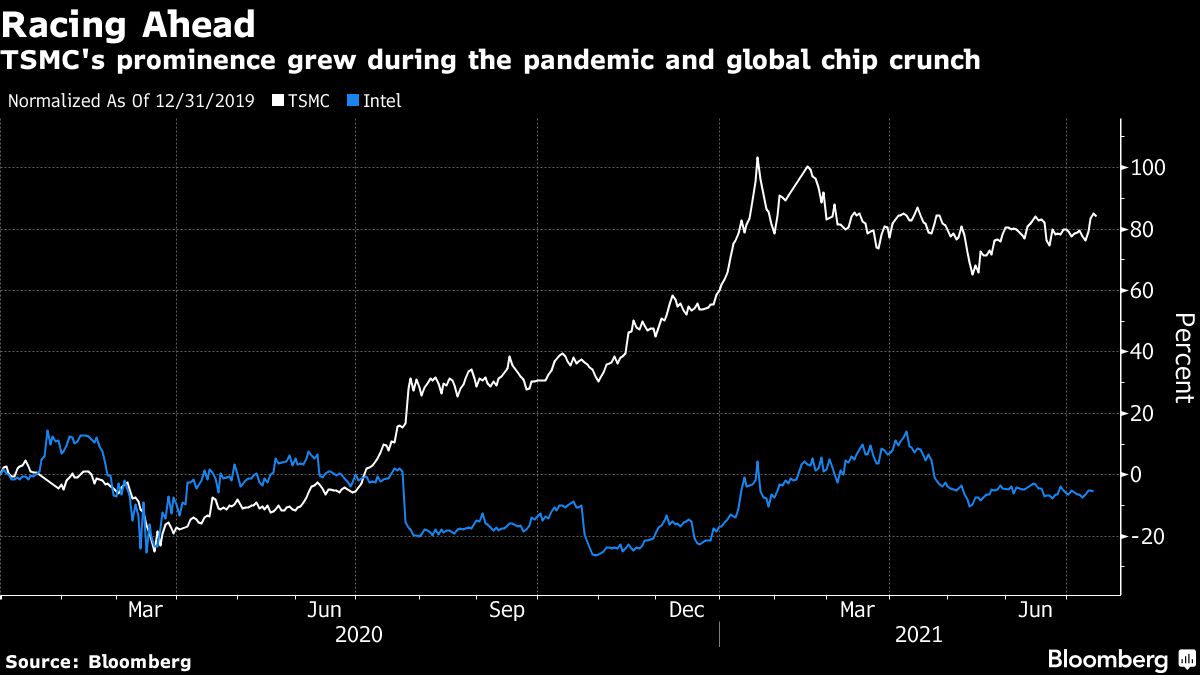

(Bloomberg) — Taiwan Semiconductor Manufacturing Co. expects sales to rise more than 20% in 2021, affirming its crucial role in helping alleviate a global chip shortage that’s walloped automaking and other industries.

TSMC, chipmaker to Apple Inc. and a key partner to many of the world’s biggest carmakers, expects semiconductor supply to remain tight into 2022, Chief Executive Officer C.C. Wei said Thursday. The company will ramp up production of microcontrollers by close to 60% this year, which will help to greatly boost supplies for its automobile clients starting in the current quarter. Executives also for the first time confirmed the company was weighing plans for a fabrication plant in Japan.

Read more: TSMC Is Considering Building a Chip Plant in Japan, CEO Says

Revenue in the current quarter may rise to between $14.6 billion and $14.9 billion, in line with the $14.7 billion average of analyst estimates. TSMC’s 2021 sales outlook marked a slight increase from a previous forecast for 20% growth in full-year sales.

TSMC, the world’s most advanced manufacturer of semiconductors, has played an increasingly prominent political role over the past year, negotiating with governments and major corporations desperate for the chips needed to power businesses and economies. The Taiwanese company’s executives, normally more comfortable talking technical specifications and technology roadmaps, addressed questions Thursday about how they’ll deal with Chinese tensions.

Taiwan’s grip on the semiconductor business — despite being under constant threat of invasion by Beijing — represents a choke point in the global supply chain that’s giving new urgency to plans from Tokyo to Washington and Beijing to increase self-reliance.

“Everybody wants to have a peaceful Taiwan Strait,” Chairman Mark Liu said. “No one wants to disrupt” the semiconductor supply chain in Taiwan.

While an ongoing semiconductor shortage has hampered the global economic recovery from Covid-19, suppliers like TSMC, the world’s largest contract chipmaker, are among beneficiaries as they race to fulfill orders. The Taiwanese company is also likely to get a lift from plans by Apple Inc., its largest customer, to ready 90 million units of upgraded iPhones for the second half of this year.

In early July, Daimler AG and Jaguar Land Rover warned that sales will be further curtailed by the persistent chip shortage, with the latter saying deliveries in the second quarter will be 50% worse than initially thought. The U.K. economy’s growth slowed to 0.8% in May, partly due to a 16.4% slump in the production of transport equipment triggered by a lack of semiconductors.

TSMC revenue from automotive clients increased 12% from the first quarter, while high-performance computing climbed by a similar magnitude. Sales to smartphone clients, the biggest chunk of its revenue, eased 3% in the seasonally slower second quarter.

“TSMC has actively taken steps throughout the first half of this year and will continue to do so through the rest of the year to address the chip supply challenges” for automakers, Wei said. “We have worked dynamically with other customers to reallocate our wafer capacity to support the worldwide automotive industry.”

Net income for the quarter ended in June rose 11% to NT$134.4 billion ($4.8 billion), slightly below analyst estimates. Gross margin for the second quarter was 50%, below the roughly 51% average predicted by analysts, in part because of an unfavorable exchange rate. For the September quarter, TSMC forecast gross margin of 49.5% to 51.5%. Analysts had seen 51.5%, according to estimates compiled by Bloomberg. TSMC fell 1.5% in pre-market U.S. trading.

Meanwhile, in early June, a cluster of Covid-19 infections at a factory in central Taiwan forced King Yuan Electronics Co., one of the world’s leading chip-testing service providers, to shut operations temporarily. That led to minor disruptions in the Taiwanese semiconductor supply chain which many around the world rely on. TSMC said on Monday three of its employees were confirmed to have been infected, though it doesn’t see any impact on operations.

The CEO on Thursday revealed TSMC is currently conducting “due diligence” on whether to build a fab in Japan, which would mark a strategically important geographic expansion for the chipmaker. Any Japan fab will be for “specialty technology” — a term that usually refers to mature node chips that serve specific or niche markets, Liu said, adding that there is no final decision yet.

“If TSMC builds a fab in Japan, it is likely to build a modest mature node fab to better serve its automotive and industrial customers there,” said Jeff Pu, an analyst with Haitong International Securities Group. “By setting up a fab in Japan, TSMC will also have the opportunity to better explore non-U.S. equipment for future development.”

TSMC currently produces its most advanced chips in Taiwan, though it has a facility in Nanjing and is building a $12 billion plant in Arizona.

Click here for a liveblog on TSMC’s earnings call.

(Updates with comments on Japan fab starting in second paragraph)

More stories like this are available on bloomberg.com

Subscribe now to stay ahead with the most trusted business news source.

©2021 Bloomberg L.P.