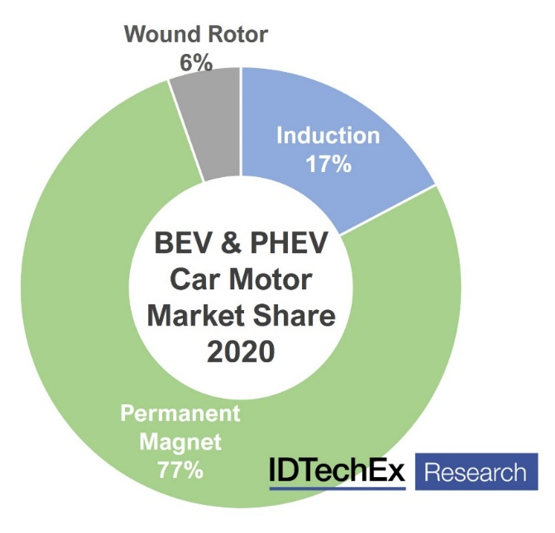

But according to IDTechEx, despite Europe’s efforts, the production of permanent magnet designs will not be completely halted given their superior efficiency and power density. In fact, in 2020, 77% of the electric car market used permanent magnet motors, a ratio that – according to the market analyst – has remained fairly consistent over the past five years.

Within this context, IDTechEx’s report states that the expectation is for neodymium volume demand from battery-electric vehicles in 2032 to be 11 times the demand experienced in 2021.

“The huge neodymium price spike in 2011 may have factored into the decision by Renault to continue with their wound rotor design and for the development of Audi’s induction motors used for the e-tron, but in general, with the settled price, we are seeing more announcements of a switch to permanent magnets,” the dossier reads.

Other carmakers like BMW are also switching to a wound rotor design, in this case for the fifth-gen drive system which will power their next-generation EVs including the iX3, i4, and others.

A wound rotor configuration uses copper windings on the rotor, while induction motors – like the ones used historically by Tesla for its Model S and X – use a copper or aluminum cage on the rotor.

Tesla, however, has been among the companies staying the course, having adopted a permanent magnet motor for their Model 3 onwards whilst keeping an induction motor on the front axle. Audi’s new Q4 e-tron for 2021 also took a similar approach.

“Whilst we have seen some differentiation in the European market, as China largely controls the rare-earth supply, the price volatility is not as much of a concern and they are unlikely to shift away from permanent magnet machines. With China being one of the largest EV markets, this means that permanent magnet motors are here to stay,” IDTechEx’s document states.

Yet, the review is quick to point out that since automotive development timeframes are long, normally on the scale of several years, a few more announcements about the reduction of rare earths in the next few years can be expected, particularly as companies factor in the neodymium price volatility seen in 2021.

After a 2.2 fold increase at the start of the year for neodymium and dysprosium, prices of praseodymium-neodymium oxide, or NdPr — two of the 17 rare earth elements that are used in NdFeB magnets — spiked to $115,000 a metric tonne last Thursday, the highest since November 2011, data from Shanghai Steelhome E-Commerce show.

“[And] in addition to the price concerns, there are environmental concerns,” IDTechEx’s report reads. “Rare earths are extracted from ores which can contain radioactive materials such as thorium and extracting the required rare earths typically uses a huge amount of carcinogenic compounds like ammonia, hydrochloric acids, and sulphates. It has been estimated that processing one tonne of rare earths can produce up to 2,000 tonnes of toxic waste. For EVs to truly be a transition to green technology something about the situation has to change.”