Capital investment firm, battery recycler join forces to boost US rare earths production

“With American Rare Earths’ first purification facility expected to be operational in the first half of 2022, this partnership further strengthens American Rare Earth’s foothold into various feedstock relationships for battery and magnet material including from spent electric vehicle and windmill motors and e-waste, for which there is currently no comprehensive, sustainable, end-of-life solution,” the media brief states. “Additionally, the partnership opens up relationships with public and private customers demanding these purified metals to drive the growth and success of the electrification and clean-tech markets while advancing national security interests.”

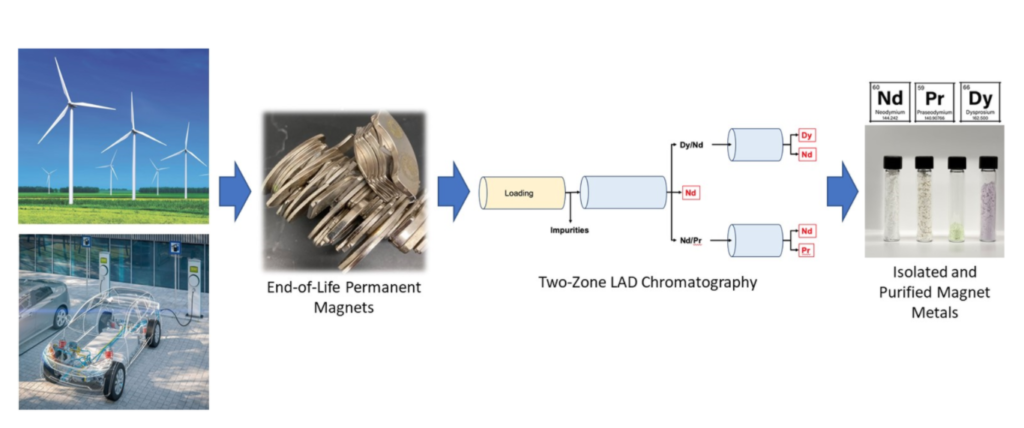

ARE’s first facility is forecast to produce 56,000 kilos of 99%+ purity of sellable rare earth elements and battery metals from a multitude of feedstocks. The process consists of capturing end-of-life windmill generators, EV motors, lithium-ion batteries / black mass, and carbon-based deposit feedstock, and then digesting them to a type of salt which is later on processed through separation displacement chromatography to isolate and purify the individual elements.

Once this pilot plant yields results, the company wants to build a purification commercial facility that is expected to operate up to 12 production trains and produce over 3 million kilos of REEs.

“We are thrilled to team up with HG Ventures and benefit from their outstanding expertise, network and shared vision to redefine how critical and rare earth elements are sourced, processed and purified as part of a sustainable, circular supply chain,” Mark Jensen, CEO of American Resources Corporation, said in the release. “Scaling up a closed-loop and circular supply of these increasingly important materials will bring impactful solutions to the domestic supply of rare earths and critical metals, and enable the US to compete on a global basis.”