After seeing Hawaii’s beaches littered with plastic, this islander built a company to make straws from seaweed

At Sunday Motor Co. Café in Madison, New Jersey, customers are sampling the latest in biodegradable non-plastic utensils. Specifically, straws made of seaweed.

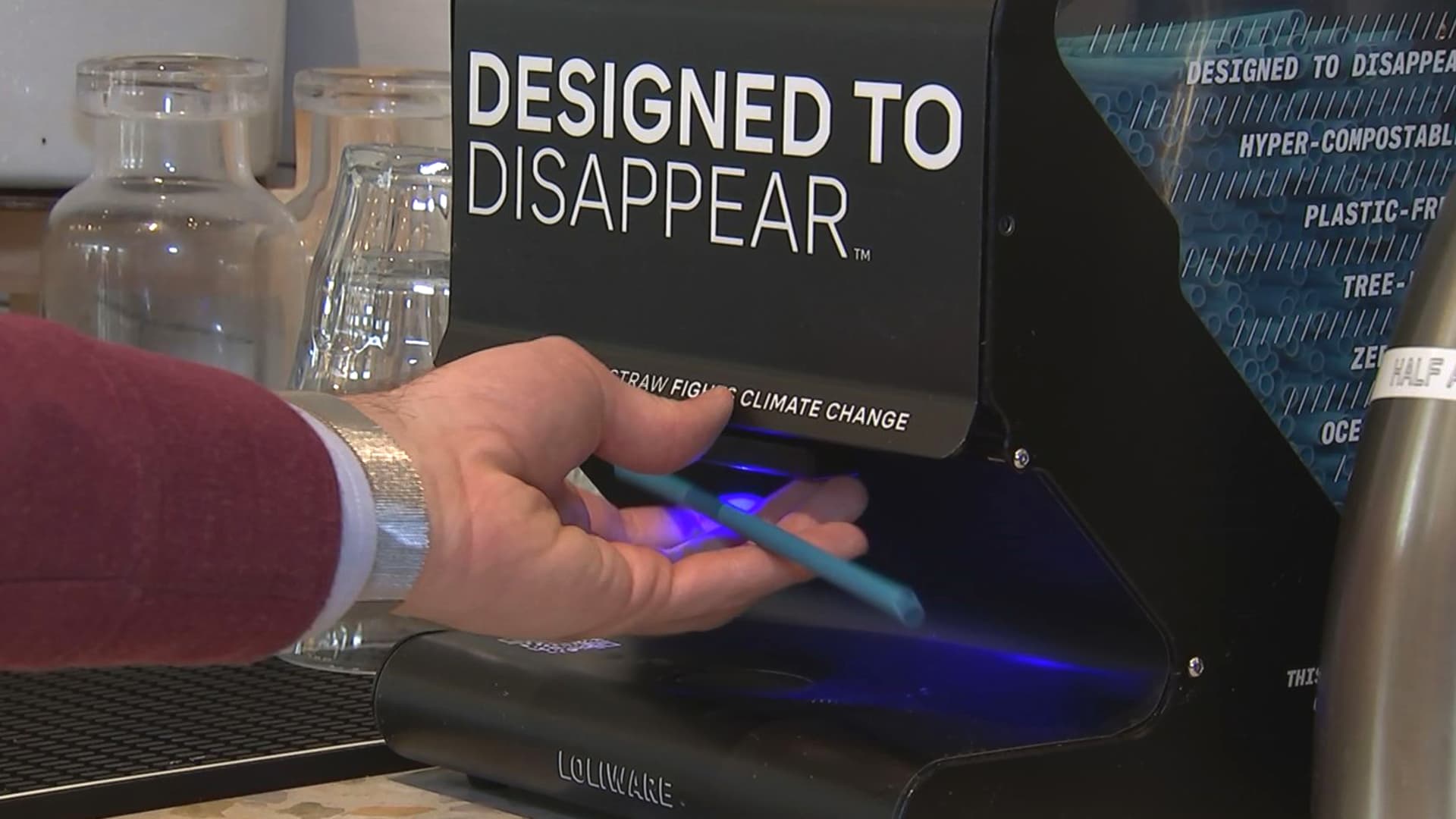

The dispenser says, “Designed to Disappear,” which is exactly what the co-founder of sustainable start-up Loliware envisioned.

Chelsea Briganti, who goes by “Sea,” was born and raised in Hawaii, where, as a child, she remembered pristine shorelines.

“And I noticed steadily over the years, as I got older, that there was a ton of plastic pollution in the ocean and on the shoreline. And of course, this had a big impact on me, watching that happen,” she said.

That’s why Brigani founded Loliware in 2015, which started in Silicon Valley and also has an office in New York City.

“The triple planetary emergency is a serious one: That’s plastic pollution, climate change and biodiversity loss, so we’ve made it our mission to address this with sea technology,” said Briganti.

Loliware takes seaweed, mills it down and then combines it with color, minerals, and water. The results are seaweed-based pellets instead of plastic pellets. These can be fed into a regular plastic production machine to make utensils.

“Sea technology is a competitive technology to replace plastic at scale, because it’s high performing, cost competitive, scalable, and regenerative. So it’s the most sustainable alternative to plastic on the market,” said Briganti.

In an increasingly competitive marketplace for plastic alternatives, Loliware’s straws seem to be passing the sip test.

“I would take this over a paper straw because this doesn’t feel soggy and it holds its texture,” said Hetal Kothari, a customer at the Sunday Motor Co Café. “I’m vegetarian, so it makes it even, I guess, more appealing to come to places which have these kinds of options.”

Renee and Vick Orderman, owners of the Sunday Motor Co Café, said they chose the seaweed alternative after sampling some soggy paper alternatives. They also found the cost, which is very slightly more expensive than plastic, a plus.

“It’s expensive for small businesses to choose sustainable, eco-friendly products, so we try to do whatever we can, and this was one of those items,” said Vick.

Loliware’s products are competitive in cost because they can be made on the same equipment as plastic. They work with Sinclair & Rush, headquartered in Arnold, Missouri, to manufacture their products on existing plastic molds. While they’re making straws now, they expect to expand into other products like cups. They also hope to use Sinclair & Rush’s worldwide production facilities to reach overseas markets.

“Next year our new model launches where we essentially offer sea technology to all manufacturers worldwide to replace dozens if not hundreds of single use plastics next year,” said Briganti.

Loliware’s biggest customer so far is the Cornerstone Restaurant Group, but Briganti said it is adding new partners quickly. Backers include H/L Ventures, City Rock Venture Partners, Sustainable Ocean Alliance, Geekdom Fund, The Field Group and Sinclair & Rush. The company has raised just over $12 million to date.