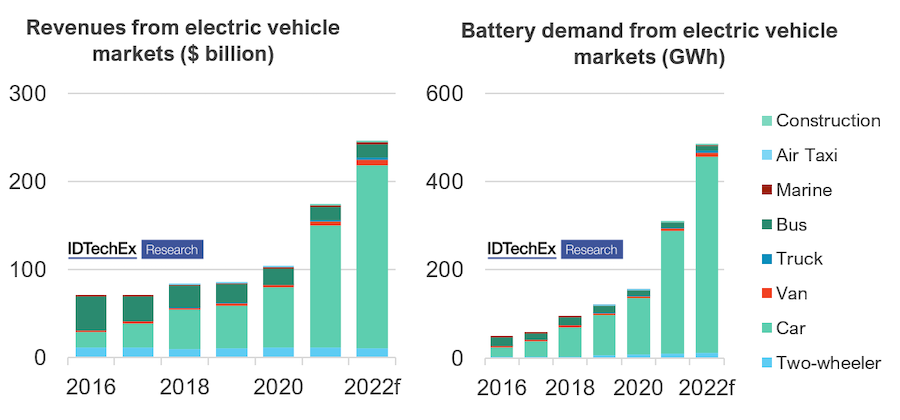

Electric cars to account for over 80% of battery demand in next 20 years despite current challenges – report

At present, electric cars are the largest market among EVs, with sales more than doubling in 2021 to over 6.4 million.

But the industry is also facing challenges, recently spurred by the war in Ukraine.

“As economies have opened up after covid-19 restrictions, and sanctions against Russia have constrained oil and gas supply, electricity prices and gasoline prices have climbed. This brings electric vehicle markets to the forefront, but at a time when automakers grapple with a lingering chip shortage, new covid lockdowns in China, increased raw material prices, and shortages of auto parts produced in Ukraine, like wire harnesses,” the report points out.

IDTechEx data show that many electric vehicle makers have started to react to the new context by increasing prices or delaying and limiting production.

“The price increases are not trivial. In 2020, Tesla’s base Model 3 cost $39,990 – in 2022 it is $46,990. In March, Rivian announced it would increase the price of its models by up to $14,500 (R1T), before facing a customer and investor backlash. Beyond the start-ups, automotive giant VW announced it has effectively sold out of electric vehicles in the US and Europe for 2022,” the document reads.

The dossier explains that batteries remain the largest cost component of electric vehicles, and climbing costs of battery raw materials, particularly lithium and nickel, are a factor behind the increases. This is driven by shortages and new lockdowns in China as well as the Russia-Ukraine war. Most of the world’s lithium is processed in China, and Russia accounts for around a fifth of global class 1 nickel supplies.

“As shortages continue, and supplies of electric vehicle parts are eaten up by the automotive sector, this will have an impact on non-automotive sectors which use the same technologies,” the report states. “An example is electric truck markets, which IDTechEx predicts will have the second-largest battery demand by 2042. Tesla’s Semi, a battery-electric class 8 long-haul truck, was originally to be produced in 2020; the target is now 2023. The Semi requires new large-format 4680 cells, but limited battery production has been prioritized for high-in-demand cars which generate more profit per kWh.”

IDTechEx mentions that electric leisure boats may also have to look at new deals with new suppliers as shortages continue.

“While non-automotive sectors demand fewer batteries, they still demand them. Improving the efficiency of the overall EV powertrain, rather than focusing on pure battery development, will be key – this means silicon carbide power electronics, more efficient motors, 800V platforms, solar bodywork, and less cabling,” the report reads. “What is clear to IDTechEx is that, despite the mounting challenges, demand for electric vehicles remains very strong from both consumers and governments. As the challenges mount, the transition continues.”