Tesla changes leadership and sets new goals at Nevada Gigafactory

Tesla has shaken up leadership at the Gigafactory, its sprawling battery plant outside of Reno, Nevada, and is setting new goals for the facility.

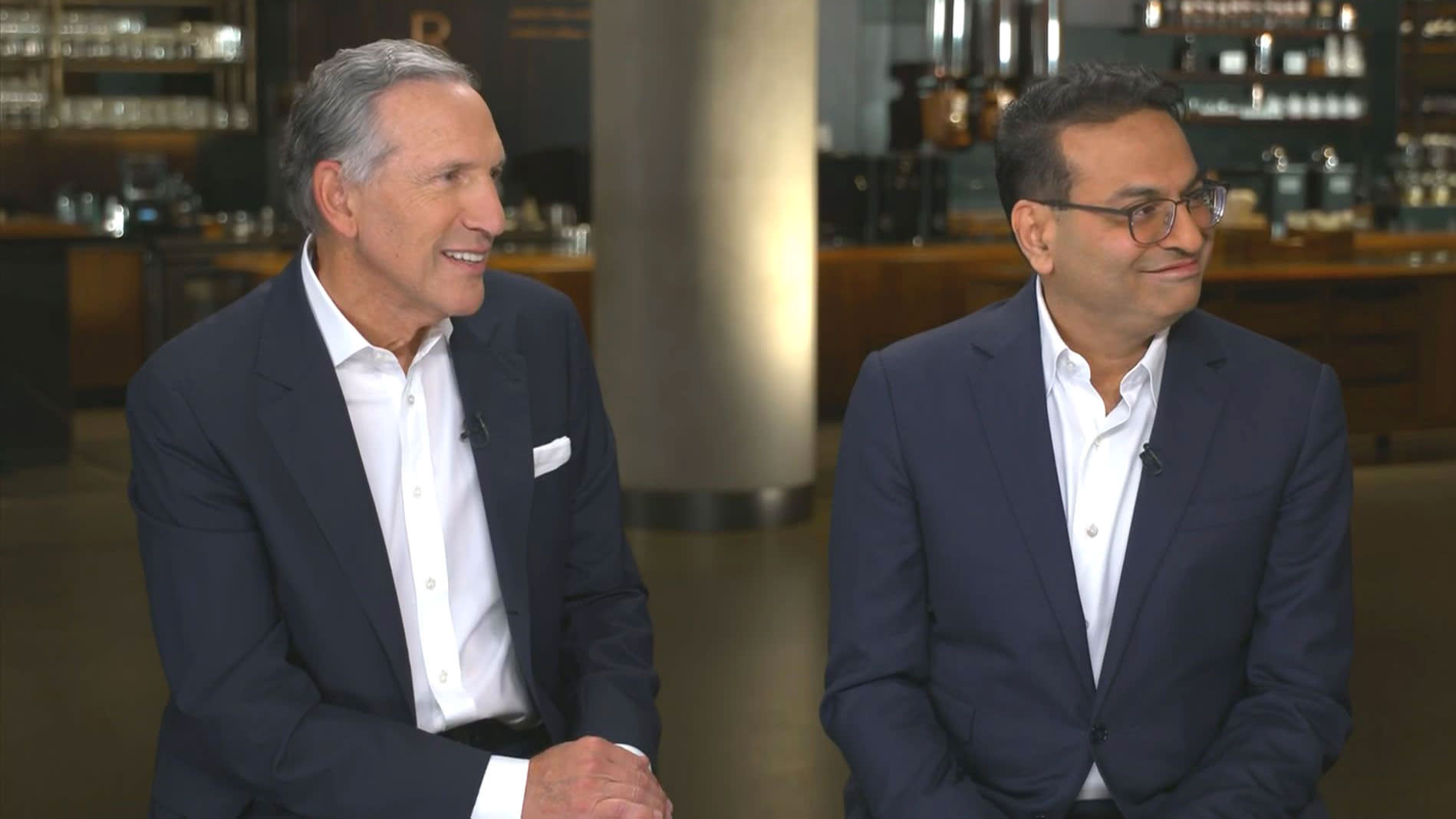

Former Vice President of Gigafactory Operations, Chris Lister, left Elon Musk’s electric vehicle and clean energy business this summer, and Hrushikesh “Hrushi” Sagar was promoted to oversee the Gigafactory, according to audio of a Thursday meeting and documents shared with CNBC by people who work at the factory. Sagar reports directly to CEO Elon Musk and will also be overseeing Tesla’s vehicle assembly plant in Fremont, California, simultaneously.

related investing news

Sagar spoke to a group of hundreds of Gigafactory employees on Thursday afternoon about management changes, performance reviews, factory milestones, and aggressive new goals for the facility. He also disclosed some information about progress in Tesla’s factories in Austin, Texas, and outside of Berlin, Germany.

Sagar briefly addressed Lister’s departure saying, “I really appreciate what Chris Lister did here, Chris’s contribution. I’m very thankful, like Elon, and Tesla is very thankful, for his contribution, but at the same time now we are moving on to the next phase.”

Workers at the Gigafactory manufacture battery packs and power trains for Tesla’s electric vehicles, as well as the big backup batteries, Powerwall and Megapack, sold by Tesla’s Energy division.

During the meeting, Sagar celebrated the fact that Tesla made around 134,000 cars in its Fremont, Calif., factory in the second quarter of 2022, and said that August was one of the record months for Fremont in terms of production. The Fremont factory is now able to make around 12,000 cars per week and is aiming for 14,000 per week as its next goal, he said.

He also said that Tesla’s team in Brandenburg, Germany, recently hit a milestone of being able to produce 1,000 cars on a rolling seven-day basis. Musk recently visited the German factory and the company expects it to ramp production to make 5,000 cars per week by the end of 2022. Initially, Reno was sending drive units to Germany to aid in that effort.

Tesla’s new factory in Austin, Texas also hit the 1,000-per-week production rate.

In terms of drive unit production, the Gigafactory produced 283,473 power trains in the second quarter of 2022 “feeding” the company’s Fremont and Austin factories.

“You all played a very big role,” Sagar said. “I just want to say thank you from the bottom of my heart,” to the Reno team.

New leaders and goals for the Gigafactory

Before he joined Tesla in late 2017, Chris Lister spent 22 years in precision manufacturing roles at PepsiCo. During his tenure at Tesla, the Gigafactory experienced a rapid build-out and growing pains including high volumes of scrap, fires and oil spills. But in ramping up production there, he also helped propel Tesla to become the top-selling battery electric vehicle brand in the U.S. and world. Lister and Tesla did not immediately respond to requests for comment.

Sagar’s new title, according to his LinkedIn profile, is senior director of vehicle operations and manufacturing engineering.

Sagar told employees on Thursday that they should think of the Fremont factory as their “customer,” noting that vehicle production there succeeds or is hampered depending on Gigafactory shipping volumes and quality.

While Sagar does not plan to spend most of his time in Reno, he plans to work closely with leaders at the plant, including Energy Leader Matt Reddick, who joined the company about six months ago, and Site Leader Eric Montgomery, who will manage things day-to-day in Nevada. Other top leaders at the Gigafactory now include Jeff Jackson, who is heading up infrastructure for the facility, and Bert Somsin, a human resources director for the plant.

At the same meeting on Thursday, Montgomery told Gigafactory employees that they need to get to a steady output of 8,800 high voltage battery packs per week to support Fremont’s new production goals, and “maximize all-wheel-drive builds.” He said August 2022 was also the Gigafactory’s second-best month on record for production, second only to October 2021.

Reddick said Tesla can now produce 42 giant Megapack batteries in a seven-day rolling period. Megapacks are about the size of a shipping container and are used for utility-scale energy storage, often to store excess energy generated by wind or solar.

Tesla is on target to produce 442 Megapacks during the third quarter of 2022, representing an 85% growth over Megapack production in the previous three-month period.

The Gigafactory also hit and has exceeded a production rate of 6,500 Powerwalls per week. Powerwalls are the smaller backup batteries for home use that CEO Elon Musk recently promoted on Twitter amid a massive heatwave in California. The heat wave threatened blackouts, and had the state urging residents to reduce their power consumption during peak hours.

Tesla previously required customers who wanted to buy a Powerwall also to buy a solar roof from the company. The Nevada Gigafactory made 37,600 Powerwalls in the second quarter, Montgomery said, and said the facility is on target to increase that by 22% in the third quarter.

In terms of the facility itself, Jackson touted a new, advanced water treatment facility that Tesla is building on site.

“This is to going to eliminate the discharge of our site process water, or wastewater, and it’s going to allow for 98% water recycling and evaporation,” he said. “It’s a huge thing, it’s aligned with our mission.”

Jackson also gave an update on the Gigafactory’s solar roof. “Right now we’ve got about eight megawatts on the roof that we’re able to use on a daily basis, which is really exciting,” the infrastructure leader said.

Tesla also has a new food vendor on site that provides poke bowls, is building a meditation room for employees, and is making road improvements and installing more EV chargers along the roads around the facility.

On the human resources front, workers were urged to reduce the number of labor hours it takes to produce a single unit of the products they build in their teams, and to file more “take charge” notices about how to improve safety and reduce costs around the plant.

The company is moving past steep headcount cuts that took place in the second-quarter this year, and is in the midst of an extensive, performance review process, Sagar said.

One employee asked management if their equity grants would be tied to company milestones this year, and management said no. But human resources teams and managers are still figuring out who may be eligible for promotions, raises and bonuses. Sagar said by the end of September, managers should be speaking with their teams about their performance assessments.

Employees asked management to discuss whether and where Tesla’s next factory may be built. Lobbying activity by Tesla in Canada, and the company’s investments up North previously have stirred speculation of a Canada-based plant.

Sagar said, “I have some idea on the candidates but I don’t think I’m at liberty right now to disclose those candidates because of the confidentiality around some of those things.” He did offer, “There is an exciting future for North America and all around the Americas.”