Odds ‘n’ Sods: Why permitting matters

Iran in those days was permit free for the exploration business. We didn’t need permits for anything. We held mineral concessions — or what passed locally for mineral concessions — prospected pretty much anywhere we wanted, so long as we kept away from border security zones and military bases. On our concession, we could basically do anything we wanted, short of actually building a mine.

Iran has wonderfully prospective geology; thousands of kilometers of volcano-sedimentary belt that’s barely been touched by modern exploration. The economy has relied on its oil for so long that metallic mining projects were low down on the priority lost for the government. The industry remains poorly developed for such incredible geological potential; I can only imagine it’s what Chile must have been like 30-40 years ago. We came across almost the complete spectrum of intrusion-related mineral deposits in the belt. Porphyries, low sulphidation epithermals, replacement base metal systems, Carlin-type sedimentary gold — it’s an open text-book of mineral deposit types.

Over two summers, our team BLEG (bulk leach extractable gold — essentially a large stream sediment sample collected from large drainage baisns) sampled the full 2,500 square kilometers of our concession, identifying multiple targets for follow up. But our main priority was the Zarshuran gold project; a Getchell-style sedimentary-hosted gold deposit close to the small agricultural services town of Takab. The project was originally flagged because of the association between arsenic, carbonate rocks, and local intrusive centers. With hindsight, the name Zarshuran — which means place of the gold washing in Farsi — is a bit of a giveaway.

It was the site of a small arsenic mine. The structure that controlled the gold system was defined by a thick zone of soft, sulphidic fault gouge that contained huge blocks of massive orpiment; arsenic sulphide. The orpiment is bright orangey-yellow and looked almost like fresh cut meat on clean surfaces.

A constant trickle of nasty, arsenic rich water flowed out of the mine adit and ran unchecked and untreated into the local stream. With the lack of an effective permitting regime or government oversight, in my two years on site, I didn’t have a single inspection by anyone from the local environmental or mines departments (if there were any). The official inertia extended to mine site accidents. We had one serious drilling accident that left an off-sider critically ill, but despite reporting it to the local police — and expecting them to launch some form of an enquiry — they just asked why we’d called. None of their business apparently. They told us accidents happen, Inshalla.

The absence of regulatory oversight meant we had to take things into our own hands. We brought in a British consultancy and started a bench-line environmental survey — soil, water, air pollution, dust — and were careful to notify the authorities in Tehran whenever we wanted to ramp up our exploration efforts, not that they seemed to care.

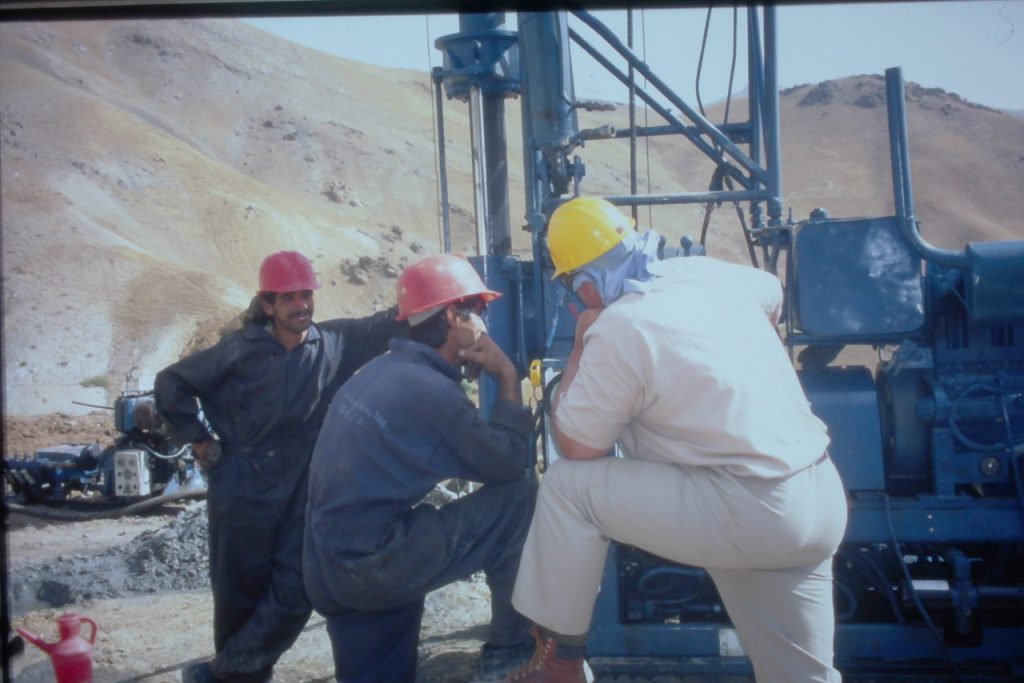

In 1996-97, I supervised two summer drill programs at Zarshuran. By this time I had fallen in love with rural Iran. Northern Iran is largely populated by Turkic people; a culture I was familiar with after spending two years in Turkey starting in 1993. And despite the frustrations of dealing with ineffective and apathetic bureaucrats at every level, it was still a safe place to work, which counts for a lot to most field geologists.

We built a small drill camp at the site, big enough to house a crew of Australian drillers, geologists and all of the other hangers-on needed to keep things ticking along. The drilling conditions were challenging so we’d hired an experienced technical drilling consultant, Dave from Australia, to help out. He was a huge bear of a man with eyes that looked in two different directions at once, which I never quite got used to.

Camps need toilets, and toilets eventually need some sort of disposal system. My Iranian helpers threw themselves headlong into the full spirit of the permitting vacuum, and suggested piping the raw sewage down to the stream that drained from the mine.

Close to the camp, our baseline work showed that the stream water contained harmful levels of natural arsenic leached from the mineralization, and the stream was effectively dead. But arsenic or no arsenic, there was no way I’d allow the camp to vent human effluent into the stream and turn it from dead, into dead and smelly. We’d advised the locals not to drink from it close to the project site, but it didn’t deserve further contamination. As the stream wound its way down the valley, side streams merged with it and they eventually diluted the arsenic to safer levels. Further down, it became the main source of water for a number of small villages and fed a trout farm, so we had to look after it.

We were puzzling over the sticky problem of sewage disposal when Dave stepped in and sketched out a tried-and-tested Aussie design for a septic system for field camps. It involved two pits lined with bentonite clay, and some pipes, some gravel and connecting channels. It was the only practical solution we had, so I hired some locals with shovels to build it and we were finally able to connect up the mud-room, toilets and showers.

Over the summer, people did what people have to do, and inevitably, after a couple of months use, the septic pits were filling up and needed to be drained. The pack of stray, mangy dogs that hung around the camp were beginning to pay attention to them, trying to get in to them, and I knew there were bears in the area too. Bears love the smell of sewage so I didn’t want to tempt fate by inadvertently drawing them in to the camp.

The nearest town, Takab, was about an hour’s drive away. It was the only place nearby that had a tanker truck for hire to handle the job. So, we arranged for the “disposal company” (I use that term lightly) to come by and pump it out. Unusually for Iran in those days, the driver showed up on time. He was in a ratty old pick-up truck — an Iranian built copy of an old Toyota design — with a nasty looking honey wagon tank perched on the back. The tank had once been a bright, happy red colour — small patches of paint were visible here and there — but years of abuse had turned it the same colour as its contents and he really didn’t need to advertise what it was used for.

A disgusting rubber pipe was curled up on top of the tank, and a small pump had been mounted on the very back of the contraption. Given the nature of his day to day job, the driver seemed unusually cheerful, always a warning sign to me; it generally meant that we — the rich foreign mining company — were paying too much for whatever service we’d hired. Sewage Man put on his coveralls and a huge pair of rubber gloves and proceeded to stick the pipe deep into the first pit. After a few failures, he fired up the pump, which complained bitterly and made some worrying gurgling noises as it pumped.

He partially drained the pit, filling up his rancid tank. Then he announced that he had to go and get rid of the first load at his facility. He drove off at alarming speed down the steep mine access road, bearing in mind the nature of his load. Takab was an hour away and I mentally allowed for two to three hours before he’d be back.

A scant ten minutes later he was back with an empty tank, and started pumping out a second load.

At this point, all sorts of alarm bells and warning claxons were going off full volume in my head. Despite our freedom from permits, if the sewage hadn’t been disposed of properly we’d probably be liable for clean up costs. At the very least, we’d be professionally and morally obliged to sort out the mess even if there was no official requirement to do so.

The burning question was where had he emptied his tank? A few thousand liters of fermented poop isn’t easy to hide. I called over Payman, my English-speaking Iranian colleague, and we investigated. Turns out that the driver had pulled off the road, five minutes down from the mine, and emptied the entire load into the stream, just upstream from the first village. There was zero appreciation for any basic environmental stewardship, something that I’d seen repeatedly throughout my time in Iran. We remonstrated with him.

You can’t do that. I said. Do NOT dump sewage into a stream.

Fine. He said. I won’t do it again.

Good, because I won’t pay you if you do. I said.

He pumped out a second load from the septic tanks and off he went again. This time he was back after about half an hour but it was obvious once more that he hadn’t driven to his facility in Takab. After a heated Q&A, he told us that he’d driven a little further down the road to a local beauty spot — a small cave by the side of the road with a fresh-water spring, where the villagers have family picnics, and let their kids splash around in the water on hot days. The cave overlooked the stream where he’d dumped the last load.

After running his hose into the cave, he’d pumped the second load of waste into it, turning a happy family gathering place into a festering swamp. He’d then stopped for a cigarette and waited long enough to make me think he’d done the job properly and headed back for his final load.

He didn’t get a chance to pump any more muck and I told him very clearly that he wouldn’t be paid unless he went back to the cave and pumped out everything he’d left there. I think in the end, it was only when I threatened to tell the villagers his name and which company he ran, that he got worried enough to go back and sort out the mess.

The moral of the story? Next time you’re tempted to complain about your project’s permitting requirements, remember they don’t just cover your activities. They also cover the companies that work for you and for good reason. In many countries, the continued absence of effective official checks and balances allows some service companies to get away with blue murder -in this case, brown murder. In the end, we’re all responsible for the mess we make, and it’s incumbent on project management to hold everyone accountable for their actions including contractors and work to the highest industry standards. Sure, it’s extra work and a pain in the butt, but it’s vital.

—Ralph Rushton is a geologist and has worked at mines and exploration projects around the world including stints in South Africa, Turkey, Bulgaria, Yemen, Iran and Pakistan. He is currently the president of Aftermath Silver (TSXV: AAG; US-OTC: AAGFF), a silver development company with projects in Chile and Peru. In his spare time, he writes about mining and exploration for his popular blog, urbancrows.com. He graduated with a geology degree from Portsmouth Polytechnic in the U.K., and completed a masters degree in geology at the University of Alberta researching the source of the placer gold in the Klondike.